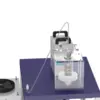

15KW Induction melting furnace with top-suction casting for thin rod up to 1200℃

It is a 15KW induction heating / melting system with a top-vacuum-suction mechanism. This unique structural design casts the product (3-5mm diameter alloy rod) by drawing molten metal directly into the top quartz tube.

Product Description

The 15VSC stands out as a 15KW induction heating/melting system, featuring an innovative top-vacuum-suction mechanism that distinguishes its structural design. This distinctive approach facilitates the casting of 3-5mm diameter alloy rods by drawing molten metal directly into the top quartz tube. The vacuum suction casting device exerts a suction force, swiftly moving the melt to expedite solidification within the quartz tube. Employing the suction casting method effectively reduces alloy shrinkage defects, making it an ideal tool for preparing small-diameter alloy rods.

The induction melting system, meticulously crafted for efficient metal processing, incorporates pivotal technical parameters. Operating on a single-phase 220V AC power supply with a working current of 34A (maximum 40A), it delivers a maximum oscillation power of 15KW and an input power of 7KW. The adjustable output frequency, ranging from 30 to 80Hz, maintains an 80% duty rate. The induction coil's dimensions are 70mm (outer diameter) by 65mm (inner diameter) by 80mm (height), integrating automatic timing features for heating, constant temperature, and cooling, ensuring precise control. The system, air-cooled through a rear fan, features automatic safeguards for water pressure, over-temperature, and over-power protection.

The vacuum suction casting functionality allows the production of alloy rods measuring 150mm in length and 3 to 5mm in diameter, minimizing alloy shrinkage defects. Manual operation generates suction by rapidly moving the syringe piston, and an observation window (Φ12) on the top flange facilitates monitoring of the melt condition. The quartz tube (7mm outer diameter × 4mm inner diameter × 500mm length) supports suction casting, with a casting alloy temperature limit of 1200°C to prevent damage. The system includes a 5mm thick alumina refractory liner encompassing the bottom crucible support, crucible, and cover plate. Accessories consist of a 1.5"OD × 1.25"ID × 3.75"(Deep) graphite crucible, with an optional boron nitride crucible (30 O.D × 24 I.D × 26 H mm). A sealing flange with a high-temperature silicone O-ring, self-tightening structure, two needle valves, and vacuum gauges enhance functionality.

Connecting to the vacuum pump through a KF25 connector and a 1000mm long bellows, the semi-open quartz tube (60mm outer diameter × 52mm inner diameter × 225mm length) ensures seamless integration. The safety valve maintains pressure control at or below ≤0.02MPa. The system includes a water chiller with a temperature range of 2 to 35°C and a water flow rate of 16L/min, housed in a 6L stainless steel tank. Specific coolant usage is recommended for optimal performance, and a brief cooling period post-heating tests is standard. The included 156L/min two-stage rotary vane vacuum pump operates on a single-phase AC 208-240V 50/60Hz power supply, boasting high power rated at 4KW. The physical dimensions include an 800mm × 600mm × 1000mm induction heater, a 460mm × 475mm × 762mm water cooler, and a 600mm × 800mm movable furnace platform. The net weight of the entire system is approximately 135kg, emphasizing its robust and comprehensive design.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.