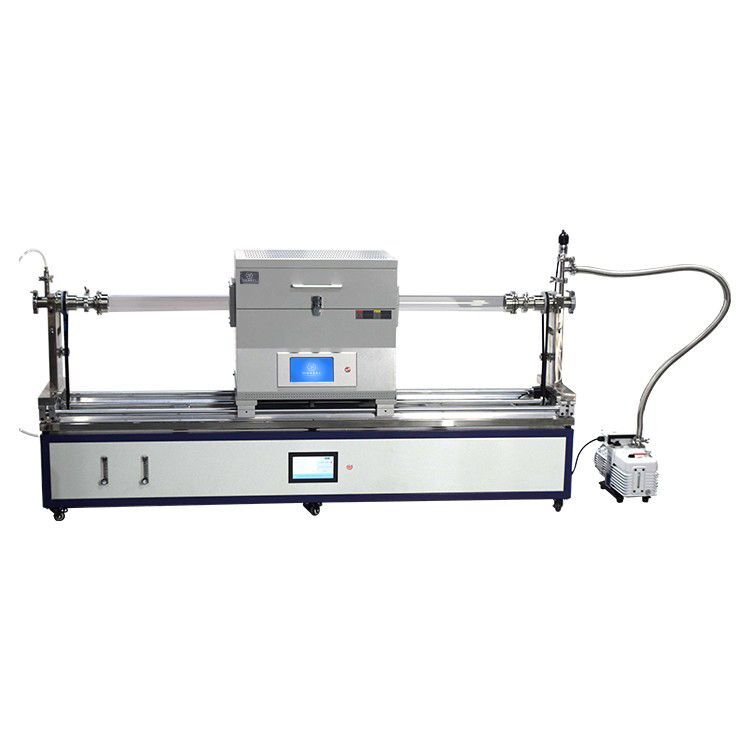

Desktop dual zones sliding rotary tube furnace

This is a double temperature zone slide tube furnace. There is a mixing partition board in the middle of the furnace tube, which can mix the powder and particles repeatedly with the rotation of the furnace tube. Through the mechanical drive, the working pipe can rotate 360°continuously, so that the materials in the tube can be mixed and heated evenly.

Product Description

The dual-temperature zone slide tube furnace, specifically the O1200-60IIT-R model, is an advanced heating system designed for precise material processing in a controlled environment. The furnace tube, made of high-purity quartz, features a diameter of 60mm and an impressive length of 1600mm. Notably, a mixing partition board within the tube enables the repeated mixing of powders and particles as the furnace tube rotates continuously through mechanical drive, providing uniform heating. The furnace body's sliding capability on the support facilitates rapid temperature changes. This dynamic system is ideal for continuous coating and modification of powder materials using the CVD method within an atmosphere-protected environment.

Operating at a power capacity of 3KW, the furnace allows precise temperature control within a range of 0~1150℃, with a limit temperature of 1200℃. Temperature management accuracy is maintained at ±1℃, supported by a 30 or 50-segment program temperature control mode accessible through a high-definition full-color LCD touch screen. The sealing mechanism, a 304 stainless steel vacuum flange, ensures a controlled environment within the furnace chamber. The AC power supply operates at 110V and 50/60Hz, with a capacity of 2.5kW.

This rotary tube furnace incorporates a 2030mm slide rail, offering a sliding range of 1500mm for enhanced flexibility. The rotation speed control ranges from 0 to 20rpm, allowing for precise adjustments. Gas flow control is managed through a 2F flowmeter, featuring two gas channels using float flowmeter technology. Channel A controls gas flow in the range of 0-160mL/min, while channel B allows control in the range of 0-100mL/min, ensuring accuracy at 4%. The pipeline pressure is maintained at 3Mpa, utilizing stainless steel pipes, and the flowmeter operates at 1 standard atmospheric pressure with φ8mm quick screw connectors for the pipeline interface.

The vacuum system, a crucial component of the rotary tube furnace, integrates a two-stage rotary vane pump with a pumping speed of 1.1L/s. Connected through a KF16 suction connection, the pump achieves a pump limit vacuum of 10E-1Pa. The vacuum system operates on AC 110V, 50/60Hz, providing the necessary conditions for precise and controlled material processing within the innovative rotary tube furnace.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.