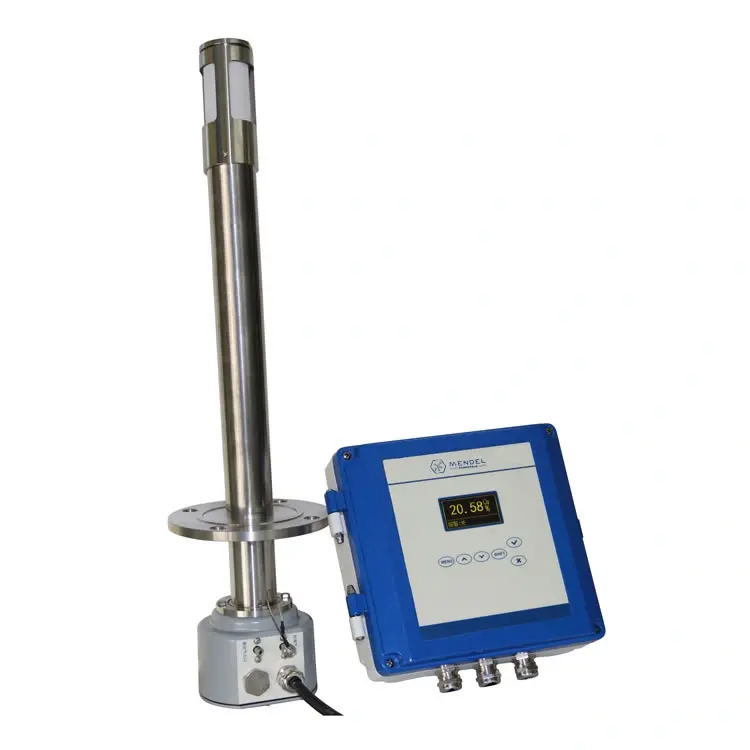

Flue oxygen analyzer

Flue oxygen analyzer is widely used in metallurgy, chemical, electric power, heating, environmental protection and other industries to analyze the oxygen content of flue gas in various industrial boilers and kilns; the control of pollutants in medical garbage incinerator; configure CEMS to control pollution emissions; the application of steelmaking refining furnace VOD.

Flue oxygen analyzer has a variety of fault information prompting functions. Self-contained fault detection function can improve troubleshooting efficiency and self-protection ability. PID automatic temperature control circuit, fast and accurate heating, can eliminate the influence of external environment on temperature control. With its own fault detection function, it can improve the efficiency of troubleshooting and self-protection ability.

Product Description

The flue oxygen analyzer stands out with its impressive technical features, providing users with accurate and intuitive oxygen content assessments. The instrument features a high-bright OLED active light display that offers a clear and visual representation of measurements. Utilizing an advanced zirconia sensor, the analyzer ensures minimal drift, rapid response times, and exceptional precision. To enhance sensor durability and extend service life, a protective coating is applied to the sensor's pipe wall where it contacts flue gas, effectively mitigating corrosive effects.

The oxygen probe, crafted from new high-temperature alloy steel, can be directly inserted into furnace chambers operating at temperatures below 650℃. Calibration is simplified with a two-point calibration process, ensuring measurement accuracy across the entire range. The IP54 protection class for both the probe and meter guarantees reliable performance in challenging environments (except for the probe front end). Users can tailor the analog output to their needs, choosing between 4-20mA (default) or 0-10V (optional) corresponding to upper and lower limit values for higher precision output. Additionally, the analyzer supports standard RS232 (default) or optional RS485 communication interfaces, facilitating two-way communication with computers and other digital devices for seamless data exchange and control.

Built on a zirconia-based measuring principle, the flue oxygen analyzer incorporates a 128×64 dot matrix OLED display for clear and comprehensive data presentation. Covering a measuring range from 0.01% to 21.00% O2, it ensures precise measurement accuracy of less than ±1.0% FS and excellent repeatability of less than ±0.5% FS. Long-term stability is maintained with deviations of less than ±1% FS over 24 hours. The swift response time, with T90 values below 5 seconds, makes real-time measurements efficient. Analog output options include 4 to 20mA.DC as the default or 0 to 10V.DC, tailored to specific load resistances. Two programmable dry contact passive alarm outputs with a contact capacity of up to 220VAC/2A enhance flexibility.

The flue oxygen analyzer supports RS232 as the default communication interface, with an optional RS485 interface for versatile connectivity. Calibration is simplified with online procedures, ensuring accurate measurements across various conditions. Operating in a range of environmental conditions, the meter functions in temperatures from -10 to +50℃, while the probe accommodates environments between 0 to 650℃. Suitable for measuring oxygen content in burning fumes, excluding highly corrosive and reducing gases, the analyzer simplifies installation with a plug-in probe design and wall-mounted meter configuration. Boasting a service life exceeding 60 months under normal operating conditions, it is a reliable and efficient solution for oxygen content assessments.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.